|

| September 09, 2014 | Volume 10 Issue 34 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

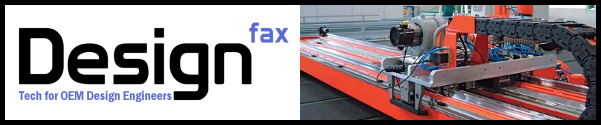

Wings:

Excess carbon fiber from Boeing 787 Dreamliner comes to the football field

Russell Athletic brand ambassador and pro football wide receiver Pierre Garcon wears the CarbonTek shoulder pad system, with an exoskeleton made of 787 carbon fiber. He is shown inside a Boeing 787 Dreamliner carbon composite fuselage. [Image: Russell Brands/Boeing]

If football players had wings, well just imagine what they could do. Now they just might get them ... sort of.

Boeing and Russell Brands/Russell Athletic are working together to incorporate excess carbon fiber from 787 Dreamliner production into Russell Athletic protective gear.

The companies are expanding an earlier collaboration that puts 787 carbon fiber into Russell Athletic's new CarbonTek football shoulder pad system. The aerospace-grade carbon fiber, it turns out, provides a high strength-to-weight ratio and impressive durability both on -- and over -- the field.

"Because Boeing is increasingly using carbon composites to build airplanes, we want to see more of our high-value fiber recycled or repurposed, which meets our environmental and business goals," says Jessica Kowal, Environment Communications, Boeing Commercial Airplanes. "We have an interest in working with companies, such as Russell Athletic, that envision new products with the fiber to generate more 'pull' from the market for it."

Other companies are using 787 carbon fiber to make kayak paddles, car parts, and baseball bats, says Kowal.

At the core of the CarbonTek with OS Technology shoulder pad system are two revolutionary materials combining for a unique protective advantage: an automotive-grade foam vest and a 100-percent, aerospace-grade carbon-fiber exoskeleton that is thinner, stronger, and approximately 10 percent lighter compared to competitor systems. The OS Compression Vest can be used without the exoskeleton for non-contact days.

The system boasts superior impact management, a lower profile, an increased range of motion, and a military-grade buckle system that provides a secure fit for the athlete.

"It's an exciting opportunity for both companies to leverage the value of carbon fiber used in high-performance gear while helping to meet environmental goals," says Robby Davis, senior vice president and general manager, Russell Athletic.

Carbon fiber used to manufacture the Boeing 787 Dreamliner. [Image: Boeing]

Boeing sees more opportunities to repurpose carbon fiber as it increases the use of carbon fiber-reinforced composites in its airplanes. The 787, which is 20 percent more fuel efficient than the airplane it replaces, has a composite fuselage and wing. Boeing's new 777X will be the largest and most efficient twin-engine jet in the world due, in part, to the industry's largest composite wing.

When "excess" is a good thing

"The surplus carbon fiber used to make Russell Athletic's CarbonTek exoskeleton includes pieces of tape that can't be used for a range of reasons, such as ends of rolls that are too short to start making a 787 fuselage or tape that has been stored past its 'use by' date and doesn't meet the very stringent standards for aerospace products," says Kowal. "The material is still aerospace-grade fiber, and there's nothing wrong with it -- it's just that we can't use it and want to find a new home for it."

The total amount of surplus carbon fiber or composite scrap from Dreamliner production varies based on a range of factors, from production rates to production efficiency, says Kowal.

Where the excess goes is also based on a number of variables.

"Unrelated to the CarbonTek project, some processed 'composite scrap' from 787 production has been sent to composite recycling companies, which I believe use pyrolysis or another technology to recapture short strands of fiber, which they sell to other companies," says Kowal. "Boeing's long-term goal is to recapture longer, more valuable strands of carbon fiber that can be reused in aerospace products, and we fund research in the UK and other places to work toward that objective."

Video: See how a Boeing 787 Dreamliner is made for Thomson Airways, the first UK airline to fly the aircraft, by clicking here.

Several elite collegiate players from Division I universities will be wearing the CarbonTek system throughout the upcoming football season, as well as Russell Athletic's three pro football ambassadors: Pierre Garcon (wide receiver, Washington Redskins), Mark Ingram (running back, New Orleans Saints), and Colt McCoy (quarterback, Washington Redskins).

Learn more about CarbonTek with OS Technology at www.carbontekshoulderpads.com.

If your company is interested in developing products using Boeing carbon fiber, you can email Jessica Kowal, Environment Communications, Boeing Commercial Airplanes, at jessica.m.kowal@boeing.com for details.

Source: Boeing

Published September 2014

Rate this article

View our terms of use and privacy policy